How To Install Our Latest Kool Wrap Exhaust Wrap Insulation

First, you need to work out how much of our Kool Wrap exhaust wrap do you need.

If you are wrapping smaller diameter pipes up to 37mm (1.5”), use a 25mm wide wrap. If your pipes are larger than 377mm in diameter then choose the 50mm (2”) wide wraps.

A Harley Davidson has larger primary pipes and will typically use 15m of wrap. A 4-cylinder engine will also use 15m while a V8 will require 2 15m rolls.

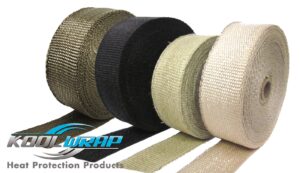

Koolwrap offers its standard range fibreglass insulation wraps in white, natural (cream or tan) and black. If you are racing, then your pipes can easily get red hot and we would then recommend our high temp range of either a Vermiculte coated fibreglass wrap or our Titanium wraps. Our Titanium wraps will withstand up continuous exposure up to 1,800°F or 980°C. The melting point is a sky high 2,500°F or 980°C.

You do not have to dampen your Kool Wrap exhaust wrap before applying as our latest high-tech wraps are more flexible than older style wraps and confirm well to corners.

However, there is no harm dampening the wraps if you choose to. It may help to get a tighter finish and can help reduce the small fibres that come off the wraps and can cause skin irritation. Always use gloves and long sleeves when applying. If you decide to dampen your Kool Wrap exhaust wrap, do not soak the wrap in a bucket. Simply dampen the wrap under a tap or use a spray bottle.

It is easier if you work out approximately how much wrap you will need for each pipe before you start and cut a separate length of wrap for each pipe. This avoids trying to pass a large roll of wrap around the pipes.

Fold over the first 15cm of wrap to avoid a fraying end and to provide a tidy start. Then overlap the first 1-2 wraps to lock it on place. You can also add a stainless steel tie at this point to firmly hold your starting point. Then wrap slowly around the pipes using 5-8mm overlap (1/4”). The overlap will naturally increase on the inside of the bends. Keep tension on the wrap to give a nice tight finish.

You can finish your wrap with a spray paint aerosol can. You could choose a clear or a colour of your choice. This will help to lock down any loose fibres and help prevent liquids and dirt from staining your wrap.

You will initially notice the wrap will smoke when you first start your engine. This will disappear after 15-30 mins.