Top 5 Reasons Why Heat Protection Wraps Are Essential for Your Engine

Heat protection wraps play a crucial role in safeguarding your engine’s performance and longevity. As engines generate immense heat during operation, managing and controlling this heat is vital. This article will explore the top five reasons why heat protection wraps are essential for your engine. From enhancing performance to preventing damage, these wraps offer numerous benefits that every vehicle owner should consider. Let’s delve into the details and discover how heat protection wraps can significantly affect your engine’s health.

Reason 1: Heat Dissipation and Temperature Regulation

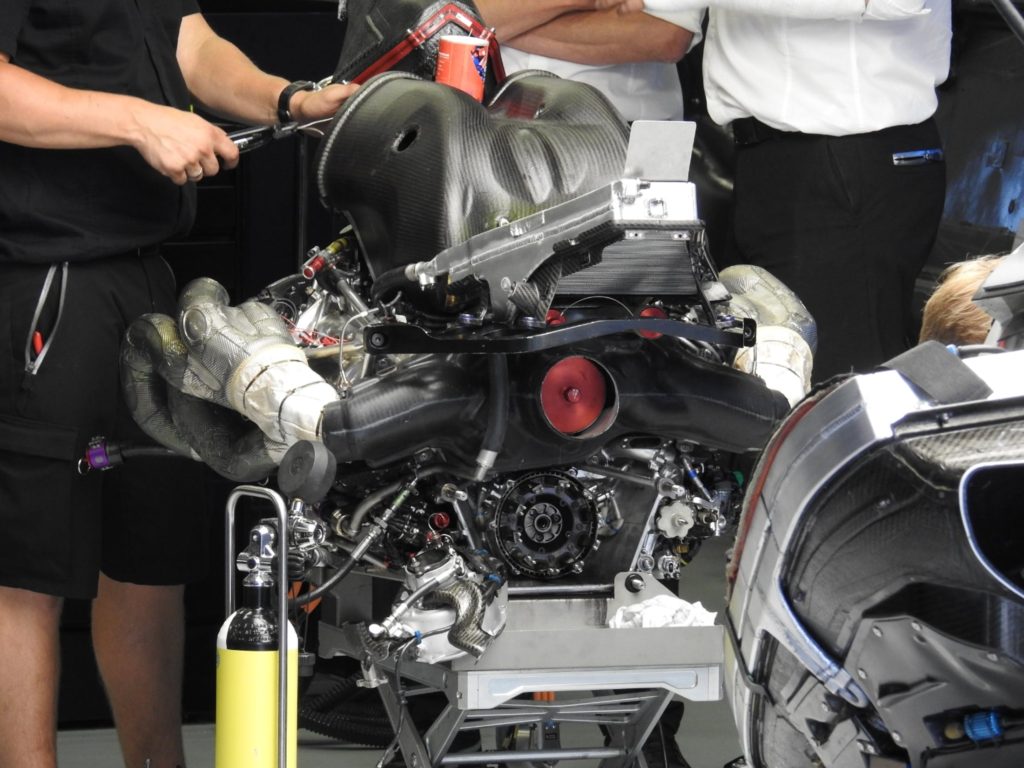

One of the primary purposes of heat protection wraps is to aid in heat dissipation and temperature regulation. By wrapping the exhaust manifold and other components prone to excessive heat, these wraps effectively reduce the temperature surrounding critical engine parts. This not only prevents overheating but also helps maintain optimal operating conditions. Improved heat management allows your engine to operate more efficiently, minimising the risk of performance issues and potential damage.

Reason 2: Protection against Heat-Related Damage

Heat protection wraps are a reliable barrier, shielding your engine components from heat-related damage. The intense heat generated by the exhaust system can lead to issues such as heat-induced cracking, warping, and corrosion. Insulating these components with heat protection wraps creates a protective layer that mitigates the impact of high temperatures. This safeguarding measure helps prolong the lifespan of engine parts, reducing the need for costly repairs or replacements down the line.

CTA

Ready to protect your engine and enhance its performance? Explore our range of heat protection wraps at www.koolwrap.com.au and experience the difference firsthand. Invest in the longevity of your engine today!

Reason 3: Improved Performance and Power

Heat protection wraps can significantly contribute to improved engine performance and power. By reducing heat soak and heat transfer to surrounding areas, these wraps help maintain cooler air intake temperatures. Cooler air is denser, resulting in a more efficient combustion process. This leads to increased power output and enhanced overall performance. Whether seeking better acceleration or improved towing capabilities, heat protection wraps can boost the desired performance.

Reason 4: Fuel Efficiency Enhancement

Efficient heat management directly correlates with fuel efficiency. Heat protection wraps enhance fuel efficiency by minimising heat radiation from the exhaust system. This reduces the likelihood of fuel vaporisation, which can occur when excessive heat affects the fuel lines. Heat protection wraps help optimise fuel combustion by maintaining lower underhood temperatures, ensuring your engine operates at its most efficient level. Enjoy longer trips and reduced fuel consumption with the added benefit of environmental friendliness.

Reason 5: Preventing Heat-Related Complications

Heat-related complications can arise from prolonged exposure to excessive heat. Heat protection wraps act as a preventive measure against these complications. They minimise the risk of vapour lock, which occurs when excessive heat causes fuel to vaporise prematurely in the fuel lines. Additionally, heat protection wraps help prevent issues like melted wiring insulation and deteriorated hose performance by reducing heat transfer to other engine components, such as wires and hoses. By investing in heat protection wraps, you proactively safeguard your engine against potential heat-induced complications.

Conclusion

Heat protection wraps are more than just accessories for engine aesthetics; they are essential components that contribute to your engine’s overall health and performance. These wraps offer numerous benefits, from managing heat dissipation to preventing damage and enhancing fuel efficiency. By incorporating heat protection wraps into your vehicle maintenance routine, you can enjoy a more efficient and reliable engine with reduced risks of heat-related issues. Make the wise choice for your engine’s longevity and invest in heat protection wraps today.

Transform Your Engine’s Performance with Kool Wrap’s Heat Protection Wraps

Discover the power of heat protection wraps for your engine. Visit our website to learn more about our high-quality products and how they can benefit your vehicle. Don’t wait; take the first step toward optimal engine health and efficiency now!